Inbound vs Outbound Logistics Explained

To truly take control of your supply chain, your inbound and outbound logistics must operate seamlessly together.

In today’s fast-moving eCommerce environment, logistics plays a central role in business operations. Whether you run a startup or manage a large enterprise, having a strong understanding of inbound and outbound logistics can significantly impact your efficiency, profitability, and customer satisfaction.

In this guide, we’ll break down inbound and outbound logistics in detail. You’ll learn their differences, core processes, strategies, benefits, key performance indicators (KPIs), and practical ways to optimize them. We’ll also touch on building an effective logistics structure for long-term success.

Let’s dive in.

What Are Inbound and Outbound Logistics?

Inbound and outbound logistics are two essential processes that move goods throughout the retail supply chain.

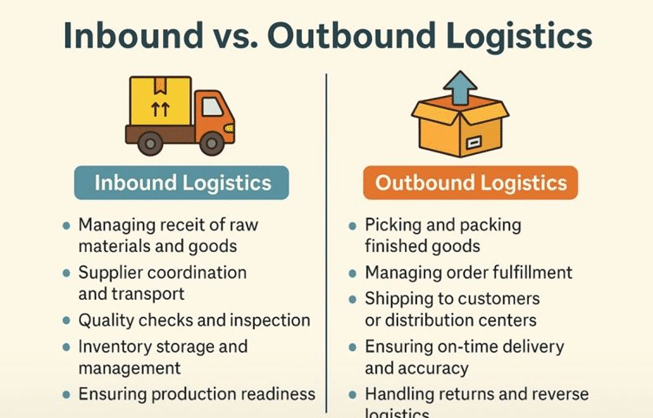

At a glance, both may seem similar since they involve transporting products across various channels. However, the key distinction lies in their purpose: inbound logistics focuses on supply, while outbound logistics centers on order fulfillment and distribution.

Inbound Logistics

Inbound logistics covers the movement of raw materials, supplies, and finished goods into your business.

It involves receiving and storing materials required for production. This segment of the supply chain manages the transportation and storage of incoming goods from suppliers to the location where they are needed. Typical activities include receiving shipments, warehousing, material handling, tracking inventory, and managing stock levels.

Additionally, inbound logistics coordinates freight transportation from suppliers through air, sea, or land. Businesses must develop structured inbound processes to ensure materials arrive in the correct quantity, quality, and timeframe.

Inbound Logistics Example

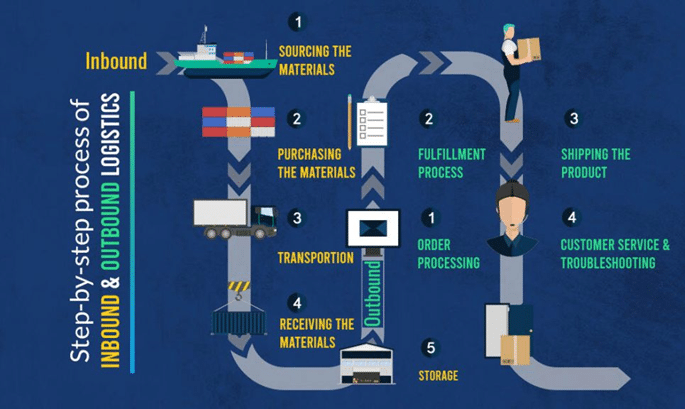

Consider the inbound process of an apparel brand, Zera Dress Co.

First, the company identifies required raw materials such as fabric, thread, zippers, and buttons.

Next, the sourcing team collaborates with designers to locate suppliers offering materials that meet quality, pricing, and color requirements.

The purchasing department then negotiates contracts and places orders with selected suppliers.

Suppliers ship the materials to the company warehouse, where the receiving team inspects quality and quantity.

Finally, inventory is organized, secured, and stored properly for future production use.

Outbound Logistics

Outbound logistics involves moving finished goods from storage to the end customer.

This process includes transferring completed products from manufacturing or distribution centers to buyers. Modern warehouse automation systems can significantly improve this stage by minimizing errors and accelerating fulfillment speed.

Key outbound activities include inventory control, order processing, picking, packaging, shipping, and delivery. It also requires coordination among warehouses, carriers, third-party providers, and customers.

In sectors such as eCommerce, efficient outbound logistics is critical because customer satisfaction heavily depends on fast, accurate deliveries.

Proper planning and execution can lower operational costs, improve delivery speed, and boost profitability.

Outbound Logistics Example

Using the same example of Zera Dress Co., outbound logistics begins once products are ready for sale.

The items are listed on the company’s eCommerce marketplace, and customer orders are collected.

Warehouse staff then retrieve products from storage and prepare them for shipment. Orders are carefully picked and packed to prevent damage. After fulfillment is completed, packages are handed over to shipping carriers.

The goods are transported via selected freight options and ultimately delivered to customers.

Difference Between Inbound and Outbound Logistics

Although both processes are connected within the supply chain, they serve different objectives.

- Focus: Inbound focuses on supply; outbound focuses on demand.

- Responsibility: Inbound manages receiving; outbound manages delivering.

- Direction: Inbound handles inward movement; outbound manages outward movement.

- Core Procedures: Inbound includes sourcing, purchasing, transportation, and receiving. Outbound includes order fulfillment, shipping, and customer service.

- Relationships: Inbound works closely with suppliers and manufacturers. Outbound interacts with customers and retail partners.

- Primary Objective: Inbound ensures materials are available for production. Outbound ensures customer orders are fulfilled efficiently.

Benefits of Effective Inbound and Outbound Logistics

Strong inbound and outbound systems are vital for overall business performance.

Improved Goods Flow

Efficient inbound processes ensure materials arrive on time and in proper condition, reducing production delays. Outbound efficiency ensures deliveries reach customers promptly and safely.

Increased Inventory and Order Accuracy

When logistics operations are streamlined, inventory tracking becomes more accurate. Orders are fulfilled correctly and delivered without discrepancies, reducing costly mistakes.

Faster Delivery Speeds

Optimized inbound operations reduce lead times by ensuring material availability. Efficient outbound systems accelerate order processing, improving delivery timelines and customer satisfaction.

Higher Sales and Revenue

When the right products are consistently available and shipped accurately, customer trust increases. Satisfied customers are more likely to make repeat purchases, boosting revenue.

Key KPIs to Track Inbound and Outbound Logistics

Logistics KPIs help measure efficiency, cost-effectiveness, and overall performance.

Inbound Logistics KPIs

Inventory Turnover

Measures how often inventory is sold or replaced within a specific period.

Freight Cost as a Percentage of Total Cost

Evaluates transportation expenses in relation to total cost of goods sold.

Lead Time

Tracks the time between order placement and material receipt, measuring responsiveness.

Outbound Logistics KPIs

On-Time Delivery Rate

Indicates the percentage of shipments delivered as scheduled.

Cost per Shipment

Calculates average shipping cost per order.

Order Accuracy Rate

Measures the correctness of fulfilled orders in quantity and content.

Customer Order Cycle Time

Tracks the time from order placement to delivery.

Return Rate

Assesses the percentage of returned orders, highlighting potential quality or fulfillment issues.

By analyzing these KPIs, businesses can identify inefficiencies and refine their logistics processes.

How to Optimize Outbound Logistics

1. Build Strong Partnerships

Develop reliable relationships with carriers, third-party logistics providers, and freight partners. Strong partnerships can improve reliability, reduce delays, and lower costs.

2. Minimize Transit Time

Analyze current shipping routes and eliminate inefficiencies. Explore faster or more economical delivery options, including express or air freight where necessary.

3. Implement Automation

Automation enhances accuracy and efficiency. Technology can track shipments, manage inventory in real time, and standardize communication with suppliers and carriers. It also reduces manual errors and improves fulfillment speed.

Before selecting a logistics management tool, carefully evaluate available software solutions based on your business size and needs.

Final Thoughts

Inbound and outbound logistics form the backbone of a well-structured supply chain.

Inbound logistics ensures a steady and cost-effective flow of materials into the company, while outbound logistics guarantees products reach customers efficiently. Mastering both enables businesses to reduce costs, improve operational control, and deliver superior customer experiences.

By implementing structured processes, tracking the right KPIs, and embracing optimization strategies, companies can create a logistics system that drives long-term competitive advantage.